Custom Adhesive Label Manufacturer in China: Why Importers Prefer Us

27 August, 2025The Future of Branding: Why Synthetic and Soft-Touch Labels Are Essential for Modern Food & Beverage Packaging

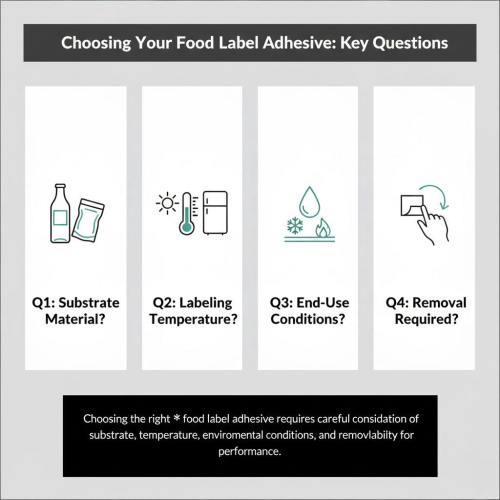

8 December, 2025In the bustling world of food packaging, the visual appeal and informational clarity of your label are paramount. But beneath that vibrant design lies a critical, often-overlooked hero: the food label adhesive. It’s the silent workhorse that keeps your brand story firmly attached, through condensation, freezing temperatures, and countless consumer interactions. Choosing the wrong adhesive can lead to peeling labels, smudged information, and ultimately, a damaged brand image. This article dives into the sticky science of food label adhesives, guiding you through the essential types and helping you select the perfect match for your product.

More Than Just Sticky: The Role of Food Label Adhesives

An effective food label adhesive does far more than just “stick.” It must form a strong, lasting bond with diverse packaging materials (glass, plastic, metal, flexible films) under varying environmental conditions. Imagine a refrigerated food label peeling off a yogurt cup in a humid cooler, or a freezer food label detaching from an ice cream pint – these scenarios directly impact consumer trust and product integrity. The right adhesive ensures your label stays put, maintaining product information and brand appeal from production line to pantry.

The performance of an adhesive depends on several factors:

-

Substrate: The material of the packaging itself (e.g., glass, PET, HDPE, paperboard).

-

Surface Energy: How easily the adhesive can “wet out” and bond to the surface.

-

Environmental Conditions: Temperature, humidity, exposure to oils, chemicals, or direct sunlight.

-

Application Method: Manual or machine application, which affects initial tack requirements.

Understanding these variables is crucial when selecting the ideal custom food adhesive label for your specific needs.

The Three Main Types of Food Label Adhesives

Understanding the core categories of food label adhesives is the first step in making an informed choice for your food packaging label.

1. Permanent Adhesives: For a Bond That Lasts

Permanent adhesives ensure a steadfast bond, making them ideal for food packaging labels on jars and bottles where durability is paramount.

As the name suggests, permanent adhesives are designed to create a strong, often irreversible bond. Once applied, they are extremely difficult to remove without tearing the label or leaving residue on the product. They offer excellent long-term adhesion and are resistant to environmental factors once fully cured.

-

When to use: Ideal for products where the label is not intended to be removed, such as:

-

Most jars (sauces, jams, pickles)

-

Bottles (beverages, condiments)

-

Canned goods

-

Any food packaging label that needs to stay intact for the entire product lifecycle, providing essential nutrition facts labels and branding.

-

-

Key Characteristics: High initial tack (sticks quickly) and strong ultimate adhesion (holds firmly over time). They are often formulated to resist moisture and temperature fluctuations within a typical room-temperature to chilled environment. Many durable food labels rely on permanent adhesives for their robust performance.